silicon carbide for grinding wheel abrasive

Basic Info

Model No.: F24

Product Description

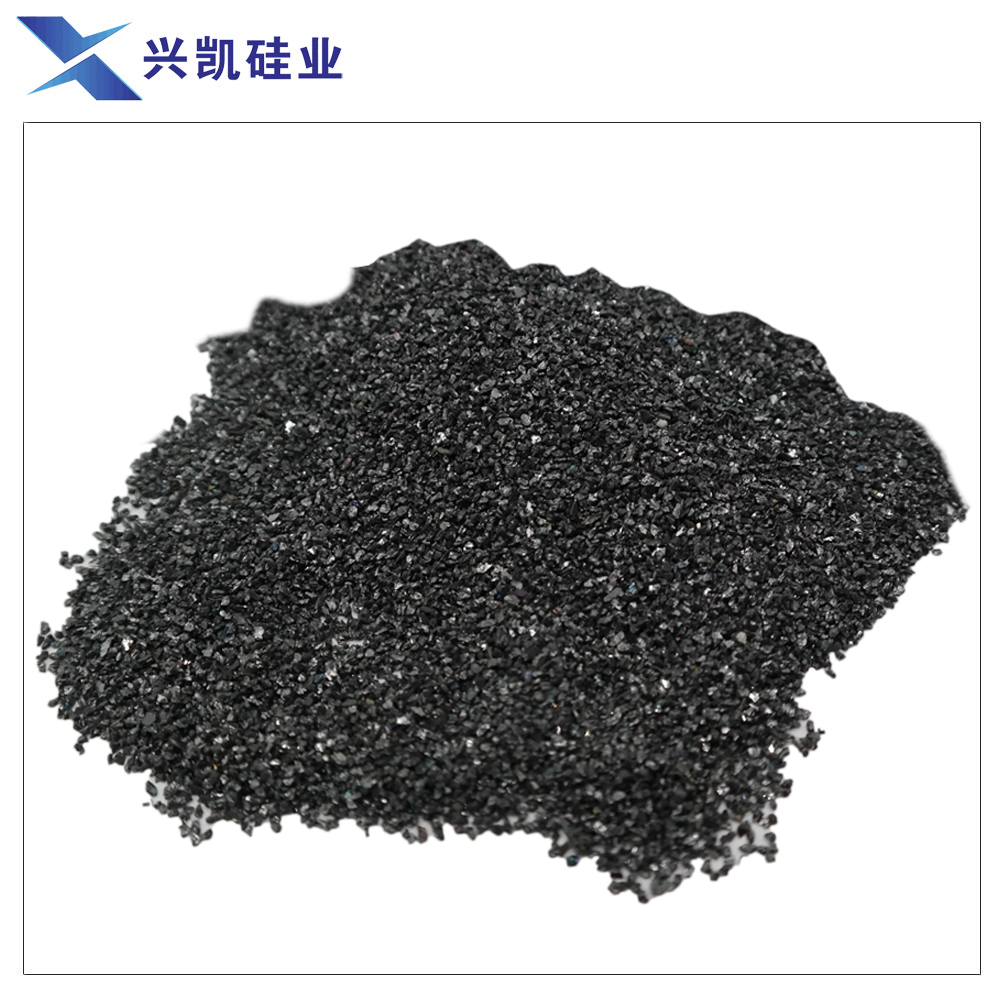

Introduction

SiC mainly used for Grinding Wheel, abrasive paper, abrasive belt, oilstone, grinding block, grinding head, grinding paste and photovoltaic products in monocrystalline silicon, polycrystalline silicon and electronic industry and other aspects of the piezoelectric grinding and polishing. Silicon carbide (SiC) is made from quartz sand, petroleum coke (or coal tar) and sawdust as raw materials by smelting with resistance furnace at high temperature. Silicon carbide also has rare minerals in nature, and silicon carbide is also called carbon silica. Silicon carbide is one of the most widely used and economically refractory materials in C, N, B and other non oxide refractory materials. It can be called alloy sand or refractory sand. At present, China's industrial production of silicon carbide is divided into black silicon carbide and green silicon carbide.

Applications

Abrasives:SiC mainly used for grinding wheel, abrasive paper, abrasive belt, oilstone, grinding block, grinding head, grinding paste and photovoltaic products in monocrystalline silicon, polycrystalline silicon and electronic industry and other aspects of the piezoelectric grinding and polishing.

Chemical aspects: SiC can be used as steel-making deoxidizer and cast iron tissue modifier, can be used to make four silicon chloride raw material, is the main raw material of silicone resin industry. Silicon carbide deoxidizer is a new type of strong composite Deoxidizer, replacing the traditional silicon carbon powder was killed, and compared with the original process of various physical and chemical performance is more stable, good deoxidizing effect, the deoxidation time shortened, save energy, improve the efficiency of the process, improve the quality of steel, reduce raw material consumption, reduce environmental pollution, improve working conditions, is of great value to improve the comprehensive economic benefits of electric furnace.

Transportation and package

1. Transportation and handling: During the transportation process, the silicon carbide shall not be dragged with hook, should prevent mixing with hard materials. It should be light unloading to reduce packaging crushing.

2. Storage: The silicon carbide should be stored in a cool and dry place, to prevent rupture of bags, to prevent moisture and other substances to affect the product. Storage should away from sources of pollution.

3. Non-flooding: The silicon carbide is high abrasive, so in the transportation, storage and the process, we must absolutely prevent flooding to insure the quantity of the products.

Product Categories : Silicon Carbide > Silicon Carbide Fine Powder