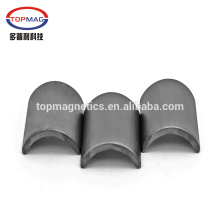

Motor Type ceiling fan brushless dc motor ring magnet

Basic Info

Model No.: YF30H-1, YF30H-1

Product Description

Product Description

What is Ferrite ?

A ferrite is a type of ceramic compound composed of iron(III) oxide (Fe2O3) combined chemically with one or more additional metallic elements. They are both electrically nonconductive and ferrimagnetic, meaning they can be magnetized or attracted to a magnet.

Ferrites can be divided into two families based on their magnetic coercivity, their resistance to being demagnetized. Hard ferrites have high coercivity, hence they are difficult to demagnetize. They are used to make magnets, for devices such as refrigerator magnets, loudspeakers and small electric motors. Soft ferrites have low coercivity. They are used in the electronics industry to make ferrite cores for inductors and transformers, and in various microwave components.

Ferrite compounds have extremely low cost, being made of iron oxide (i.e. rusted iron), and also have excellent corrosion resistance. They are very stable and difficult to demagnetize, and can be made with both high and low coercive forces. Yogoro Kato and Takeshi Takei of the Tokyo Institute of Technology synthesized the first ferrite compounds in 1930.

| Material | Hole 5mm Cylinder Radial Neodymium Magnet with Hole | ||

| Application | Neodimium Magnet n52 are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, VCMs in hard disk drives, printer, switchboard, loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, common daily use, and so on. | ||

| Size | customized size, many existing moulds and have stocks goods in the warehouse. | ||

| Price Advantage | The price is 5-10% cheaper than industry average because of an excellent and efficient management system. | ||

| Shape | block, round, ring, arc - even highly complex forms. Virtually any shape of neodymium magnet can be made to your requirements! | ||

| Performance | N33 N35 N38 N40 N42 N45 N48 N50 ... | ||

| Coatings | Nickel, Zinc, Chromium, Epoxy, Gold, Silver, Parylene, Everlube, Passivation, Copper, Chemical, PTFE and more. | ||

| Certification | ISO9001 : 2008, SGS |

Detailed Images

Producing Process

Factory

Our factory are located in Ma' anshan city,where is only 40 minutes' drive away from Nanjing.The flexibility of our organization and magnagement,high efficiency of cost control and advanced standard of quality assurance, have earned us strong partnership with several high-tech enterprises,with whom we work together in magnets reserarch and application.

High performance ferrite powder segment magnet in the fied of the auto cars and inverter appliances series ,motor startors,have reached the performance of FB6, FB9 series of TDK in Japan.

There are two principal neodymium magnet manufacturing methods:

Classical powder metallurgy or sintered magnet process[11]

Rapid solidification or bonded magnet process

Sintered Nd-magnets are prepared by the raw materials being melted in a furnace, cast into a mold and cooled to form ingots. The ingots are pulverized and milled; the powder is then sintered into dense blocks. The blocks are then heat-treated, cut to shape, surface treated and magnetized.

In 2015, Nitto Denko Corporation of Japan announced their development of a new method of sintering neodymium magnet material. The method exploits an "organic/inorganic hybrid technology" to form a clay-like mixture that can be fashioned into various shapes for sintering. Most importantly, it is said to be possible to control a non-uniform orientation of the magnetic field in the sintered material to locally concentrate the field to, e.g., improve the performance of electric motors. Mass production is planned for 2017.

As of 2012, 50,000 tons of neodymium magnets are produced officially each year in China, and 80,000 tons in a "company-by-company" build-up done in 2013.China produces more than 95% of rare earth elements, and produces about 76% of the world's total rare-earth magnets.

Bonded Nd-magnets are prepared by melt spinning a thin ribbon of the NdFeB alloy. The ribbon contains randomly oriented Nd2Fe14B nano-scale grains. This ribbon is then pulverized into particles, mixed with a polymer, and either compression- or injection-molded into bonded magnets. Bonded magnets offer less flux intensity than sintered magnets, but can be net-shape formed into intricately shaped parts, as is typical with Halbach arrays or arcs, trapezoids and other shapes and assemblies (e.g. Pot Magnets, Separator Grids, etc.)[not in citation given] There are approximately 5,500 tons of Neo bonded magnets produced each year.[when?][citation needed] In addition, it is possible to hot-press the melt spun nanocrystalline particles into fully dense isotropic magnets, and then upset-forge or back-extrude these into high-energy anisotropic magnets.

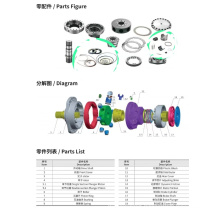

Related Products

Application:

Neodymium magnets have replaced alnico and ferrite magnets in many of the myriad applications in modern technology where strong permanent magnets are required, because their greater strength allows the use of smaller, lighter magnets for a given application. Some examples are:

Head actuators for computer hard disks

Erase heads for cheap cassette recorders

Magnetic resonance imaging (MRI)

Mechanical e-cigarette firing switches

Locks for doors

Loudspeakers and headphones

magnetic bearings and couplings

Benchtop NMR spectrometers

Electric motors:

Cordless tools

Servomotors

Lifting and compressor motors

Synchronous motors

Spindle and stepper motors

Electrical power steering

Drive motors for hybrid and electric vehicles. The electric motors of each Toyota Prius require 1 kilogram (2.2 pounds) of neodymium.[18]

Actuators

Electric generators for wind turbines (only those with Permanent Magnet excitation)

direct-drive wind turbines require c. 600 kg of PM material per megawatt[citation needed]

turbines using gears require less PM material per megawatt[citation needed]

Toys

Neodymium content is estimated to be 31% of magnet weight

Company Information

Shenzhen Topmagetics Technology Co.,Ltd have a professional rearch and development team with remarkable ablities.The products we supplied will be high quality with competitive price,best service and promp delievery.

We can fulfilling different requirement of high Br,high Hcb, or both. Our quality us prior than domestic professions and our business even extends overseas to USA, Europe, Jaapan, Southeast Asia, and so on.

We always insist that "quality first,service first", Please be welcomesd to visit for guidance and business negotiation.

Packing & Delivery

| Deliver time | if in stock will be 3-5 days | ||

| | Have existing moulds but not in stock will be 10-15 days | ||

| | need to custom moulds will be 15-30 days | ||

| Shipping | By sea: apply to big quantity goods,the freight will be cheaper,delievry time usually is 30-45 days. | ||

| | By air: the most fastest channel,delievery time usually is 6-9 days | ||

| | By land transportation: deliever to neighboring states,such as Kazakhstan,Russia,etc. usualy 18-22 days. | ||

| Payment | we can accept T/T,West Union. | ||

| | we accept Paypal (some order) |

Certifications

1.Q:Are you a factory or trading company?

A: We are a factory and we have more than 15 years manufacturing experience, we are dedicated to provide you with more competitive price.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Anhui, China.

All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A: Quality is our life, we always attach great importance to the quality controlling from the very beginning to the very end . We have QC department and strict management system such as ISO9001,TS16949 , CE, ROSH.

4.Q: How about the leading time ?

A: In generally, its 10-15 days. If some special magnets, it will be about 20-25 days.

Contact us if you need more details on Motor Type Ceiling Fan Magnet. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dc Motor Ring Magnet、Brushless Dc Fan Magnet. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Motor Parts

Premium Related Products

Other Products

Hot Products

high quality largest n42 n52 neodymium magnet D70X50free sample china ring/round shape Sintered SmCo magnet mobile phone magnetCrankshaft long axis without center grinding wheelneodymium magnet composite magnetic name badge holdersdiy service super strong lifting neodymium magnetmagnet generator prices in pakistan motor magnet making machineindustrial application tweeter dount shape neodymium magnetshard disk round steel magnet for salearc segment magnetic motor neodymium magnetHigh Precision Super Strong Magnet Cylinder Shaped Sintered AlNiCo Magnetsuper strong neodymium magnet rare earth magnet for saleN52 Neodymium magnet with backed 3M adhesive2017 new products alibaba China High Quality Aluminum Magnetic Name TagPermanent-magnetic, High Power Scrap Lifting Magnet (high power magnets)Custom Made Round shape of Ferrite Magnet Rare Earth Magnet Permanent Magnet Industry Magnetferrite magnet C5 magnet magnetic core permanent magnet dc motor