Permanent Fine Ore Drum Magnetic Separator

Basic Info

Model No.: CTB1024

Product Description

Brief Info Permanent Fine Ore Drum Magnetic Separator

The Magnetic Separator used in gold procesing plants can atorseparate raw materials with different magnetic rigidities. Permanent Fine Ore Drum Magnetic Separator are available in cyclic design with process vessel diameters smaller than 3mm. Magnetic Separator is one kind of efficient equipment for processing fine, feebly magnetic minerals, such as hematite, limonite, wolfram, ilmenite, and tantalum-niobium, etc. In recent years, Permanent Fine Ore Drum Magnetic Separator is also more and more applied in purifying quartz, feldspar and nephline. Its magnetic system is a ring-shape chain closed magnetic circuit with energizing coils made of copper tube and cooled internally by water. Grooved plates made of magnetic conductive stainless steel are used as magnetic matrix.

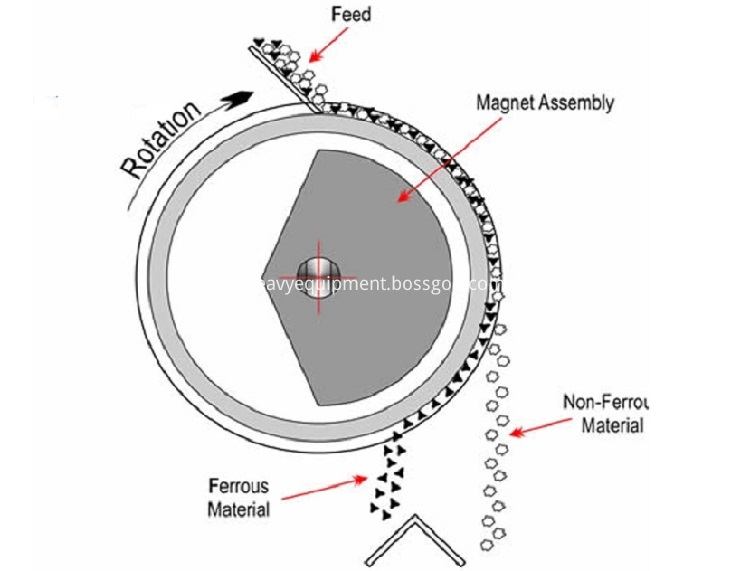

Working principle of Permanent Fine Ore Drum Magnetic Separator

When the raw materials flow into the tank body of the high Magnetic Separator price low, firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back for the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall to the ore concentrate box under gravity. Also, the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe for tailings.

Main Technical Data of Permanent Fine Ore Drum Magnetic Separator

Model Diameter(mm) Length (mm) Magnetic induction Capacity(t/h) Popwer(kw) Weight(T) CTB612 Φ600 1200 MT≤100 10-20 1.1 1.5 CTB618 Φ600 1800 MT≤100 15-30 2.2 1.8 CTB718 Φ750 1800 MT≤120 25-45 3.0 2.2 CTB918 Φ900 1800 MT≤130 35-70 4.0 2.8 CTB1018 Φ1050 1800 MT≤135 40-75 5.5 4.3 CTB1024 Φ1050 2400 MT≤135 52-100 5.5 5.2 CTB1218 Φ1200 1800 MT≤135 47-90 5.5 5.0 CTB1224 Φ1200 2400 MT≤135 80-120 7.5 6.4

Technical characteristics Permanent Fine Ore Drum Magnetic Separator

The magnetic separator combines high-performance physical magnet technology, new multi-point embroidered non-embroidered magnetic concentrating steel wool technology, solid-liquid-gas three-phase flow membrane separation technology, high-power low-voltage high-current rectification technology, PLC electronic control technology and flow, temperature and pressure testing technology.The separation magnetic field is high (up to 2.2T), the magnetic field gradient is high, and the size of magnetic field can be adjusted freely according to needs.

With programmable control, the whole production process is fully controlled and the process flow is easy to change.

Application of Permanent Fine Ore Drum Magnetic Separator

Purification and refinement of fine clay minerals (kaolin, bauxite, etc.): Removal of fine magnetic dyeing impurities (Fe2O3, TiO2) from clay ores;Reduce Fe2O3 content in quartz sand, feldspar and barite.

Reduce the content of copper in molybdenum concentrate.

Coal ash removal and sulfur removal;

Improve the quality of apatite.

Selection of rare earth minerals, seashore placer and other useful minerals.

Continuously remove the abrasive particles in the lubricating oil, recycle and recycle the lubricating oil.

Chemical, instrument and crude oil filtration, recovery and purification of catalysts and other useful materials;

Filtration of water supply and condensate in nuclear power station and thermal power station;

Purification of industrial sewage and domestic sewage;

Product Categories : Beneficiation Equipment > Mineral Separator